3D Printing

i3DÉE SERVICE

3D printing fabrication

For manufacturing and industrial sectors

Produced by

3D PRINTING

Manufacturing by 3D printing is a very interesting alternative for the production of parts in small and medium quantities.

When your needs are limited to a few hundred copies of a part, manufacturing by printing is much more advantageous than other traditional manufacturing methods.

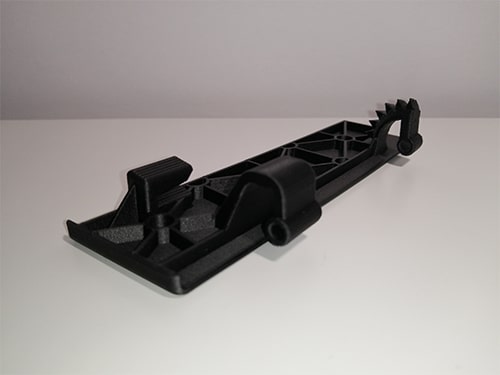

REPLACEMENT PART

You are experiencing issues with your supply of parts of all kinds. Manufacturing by 3D printing is perfectly suited to reproduce discontinued, complex or very expensive replacement parts. In addition, it is possible to obtain these parts in much shorter lead times than with the original suppliers.

PROTOTYPING

Rapid prototyping allows you to validate one or more concepts before manufacturing a final product. This is an undeniable advantage in ensuring the success of a project.

JIG AND TOOLS

You have a repetitive task to perform and which requires a certain level of precision? A positioning jig or tool developed especially for you turns out a effective and inexpensive solution.

PROTECTIVE ELEMENT

We all agree, health and safety are priorities. Sometimes the only way to eliminate a hazard is to conceal it behind a protective element. We are able to produce tailor-made machine safety devices for your equipment.

MODEL

Despite the remarkable level of realism of which virtual reality technologies are capable, a model remains a much more concrete element in the visualization of a project.

PROMOTIONAL ARTICLE

Would you like to promote an event, publicize your business or rally your employees around a cause? A well-thought-out object with attractive colors and shapes can be just the thing.

The assembly of finished products requires the manufacture of sub-components of all kinds. In many cases, these components are made of plastic using injection molding or extrusion processes.

These processes are fast and the unit cost of each part is low, provided you need several thousand copies…

3D printing offers

many possibilities

- Order only the quantity of parts needed

- No minimum quantity per order

- Allows you to easily make changes to the design of a part at a lower cost

- Manufacturing of complex parts not possible with injection molding, extrusion or even machining

- Allows "Just in time" management

3D printing is not only practical, reliable and efficient, it will allow you to get more for your money! See the comparison for an order of 500 pieces:

Injection molding: initial tooling cost of $4500, manufacturing cost of $0.25/piece, minimum quantity per order 1000 pieces, so the actual cost of each part used is $9.50.

Extrusion: initial tooling cost of $2000, manufacturing cost of $1.00 / part, minimum quantity per order 5000 pieces, so the actual cost of each part used is $14.00.

3D printing: initial tooling cost $0, manufacturing cost $5.95/piece, no minimum quantity required, so the actual cost of each part used is $5.95.

Make the comparison by yourself and you will probably be surprised at the result.

Our machine park has more than 50 high-performance machines can print in a wide variety of plastics adapted to the most demanding conditions.